The automotive industry has been constantly evolving and embracing new technologies to enhance performance, efficiency, and safety. One such technology that is making a significant impact is induction heating. Induction heating has revolutionized various processes in the automotive industry, offering numerous benefits over traditional heating methods. In this article, we will explore the various ways induction heating is transforming the automotive industry.

Improved Manufacturing Processes

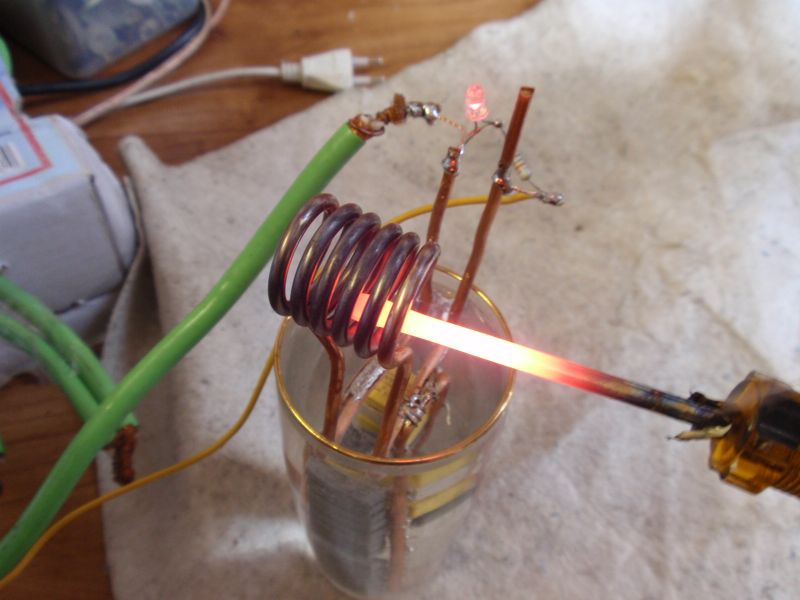

Induction heating has brought significant advancements to the manufacturing processes in the automotive industry. One area where it has made a notable impact is in the production of various metal components. Induction heating allows for precise and localized heating of metal parts, resulting in faster and more efficient manufacturing processes. The ability to heat specific areas of a component while leaving other areas cool allows for greater control and accuracy in shaping and forming metal parts, leading to improved quality and reduced waste.

Enhanced Joining and Welding Techniques

Joining and welding are crucial processes in automotive manufacturing, ensuring the structural integrity of vehicles. Induction heating has emerged as a game-changer in this regard. It offers rapid, localized, and controlled heating, making it ideal for various welding applications. Induction welding produces stronger and more reliable welds compared to traditional methods. It also enables the joining of dissimilar materials, expanding design possibilities and lightweighting opportunities in the automotive industry.

Efficient Heat Treatment

Heat treatment plays a crucial role in improving the mechanical properties of metal components used in automobiles. Induction heating has revolutionized heat treatment processes by providing precise and uniform heating. This technology allows for rapid and controlled heating and cooling cycles, resulting in improved material strength, hardness, and durability. With induction heating, automotive manufacturers can achieve consistent and repeatable heat treatment results, reducing the need for secondary operations and ensuring the overall quality of the components.

Energy Efficiency and Environmental Sustainability

Induction heating offers significant energy efficiency advantages over traditional heating methods. Its ability to generate heat directly within the material being processed eliminates the need for external heat transfer, reducing energy consumption and minimizing heat loss. Additionally, the precise and localized heating capability of induction heating reduces cycle times, leading to lower energy requirements. The increased efficiency and reduced energy consumption contribute to environmental sustainability, making induction disassembly heater a greener alternative for the automotive industry.

Advanced Surface Hardening

Surface hardening is crucial for enhancing the wear resistance and lifespan of automotive components. Induction heating has revolutionized this process by offering precise and controlled heat treatment of the component’s surface. This technology enables the formation of a hardened layer while maintaining the desired core properties of the material. The localized heating capability of induction heating ensures that only the surface is hardened, reducing distortion and preserving the integrity of the component.

Conclusion

Induction heating has emerged as a transformative technology in the automotive industry, revolutionizing manufacturing processes, joining techniques, heat treatment, energy efficiency, and surface hardening. Its ability to provide precise, rapid, and localized heating has led to improved quality, reduced waste, enhanced efficiency, and increased sustainability. As the automotive industry continues to evolve, induction heating will play a pivotal role in driving innovation and shaping the future of automobile manufacturing.