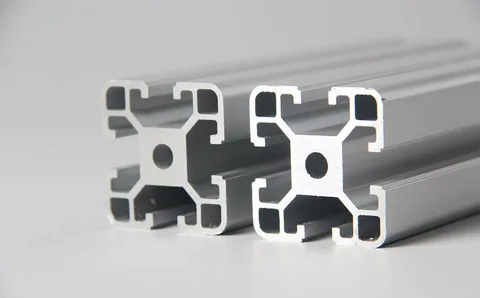

Aluminium extrusion profiles are commonly applied in many industries because of their flexibility, durability and low density. The process entails the suffusion of aluminium through a die to attain particular shapes and designs to meet the requirements of various sectors. These profiles are used in construction, automotive, electronics, aerospace, renewable energy, etc., making them significant in today’s world. Their material properties which include corrosion resistance, recyclability, energy efficiency, and the ability to be incorporated in different forms of designs make them preferred materials in various manufacturing processes. Thus, with industries setting up sections and establishing new products and services along with innovations in the existing structures, the use of aluminium extrusion profiles remains high, especially in a country like India, which is a developing country and obtaining advances in industrial structures and infrastructural developments.

1.Understanding the Aluminium extrusion process

The aluminium extrusion process is a complex one and several stages are followed to get the final profile. First, aluminium billets are placed in a furnace where they are heated and then pressed through a die to the shape of the opening. After extrusion, the aluminium is cooled before it is stretched and cut into the required length. Due to the features of this process, it can produce complex shapes and designs that can be ideal for certain uses. This process guarantees that aluminium extrusion profiles are utilizable in all sorts of industries, making it a fundamental manufacturing technique in today’s production departments.

2.Aluminium extrusion profiles in the construction market

The construction industry is one of the largest utilizers of extruded products and aluminium extrusion profiles in particular. These profiles are widely applied in the production of windows and doors, curtain façades, roofs and structures, and frameworks.

Another advantage of using aluminium is that it is relatively light which means that it requires less effort to move and fix hence saving on labour and time. Moreover, its corrosion properties also make it highly resistant to rust hence enhancing its durability for use in most homes and other structures. The increased focus on green construction and energy-efficient buildings has expanded the need for aluminium extrusion profiles in the construction industry of India.

3.Aluminium extrusion company in India: A booming industry

India has a vast aluminium extrusion industry, established by various companies and has thus offered itself as a strong contender in the global aluminium extrusion market. Today, the aluminium extrusion industry in India has observed considerable growth due to the growth in industrialization and infrastructural developments. This sector has seen organizations pump resources into the technological and marginalization of the processes as they strive to answer to the increasing demand. The aluminium extrusion company in India is integrating sustainability and innovation into the product range to meet the domestic demand as well as to expand the share of export markets, which can place the country among leaders in the industry.

4.Use of Aluminum extrusion profiles in automobile

Manufacturing Automotive is another industry that widely employs aluminium extrusion profiles. With an emphasis on weight reduction due to the need to enhance efficiency and emissions, aluminium is replacing sturdier and heavier products such as steel in construction cars. Automotive application: Aluminum extrusions are also used in the creation of vehicle frames, engine parts, chassis, heat exchangers, etc. Through the extrusion process, sophisticated shapes and designs can be created to produce automotive components that are both lightweight and tough, leading to improved automobile performance and features. The aluminium requirement in automobile industries depends directly on the electric vehicle market in India which is expected to grow more in the future.

5.The use of Aluminium extrusion in renewable energy projects

There are various reasons why aluminium extrusion profiles are important in the design of renewable energy systems, particularly solar and wind energy systems. In solar energy, aluminium profiles are used to make frames for placing solar panels to ensure strength and withstand harsh environmental conditions such as winds, rainfall and powerful ultraviolet radiation. These frames are also relatively lightweight and easy to transport and install, although they are also strong and stable. It also plays a vital role as an alloying material in the formation of lightweight components for wind turbines, resulting in improved performance due to lower mechanical stress. Aluminium is used in these renewable energy applications to decrease system mass, thus increasing productivity and lowering the cost of installation.

6.Sustainability as a business strategy for the Aluminium extrusion profiles industry

People always attend to the environmental issues that are around them, and aluminium is well known to support the green manufacturing environment. Aluminium is one hundred per cent reusable material, it can be reused over and over without restriction in cycle or turn and more.

Aluminium is 100% reusable and its lightweight nature also reduces emissions in transportation as well as energy when manufacturing. Several organizations and industries across the globe are currently practicing environmental sustainability, and this aluminium extrusion company in India is no exception with increasing green practices in the organisation. Speaking of aluminium extrusion profiles, the future is more about its potential to facilitate the construction of a society that is ever-growing to be sustainable and energy efficient.

7.Strengths and challenges that the Aluminium extrusion Industry in India exhibit

The aluminium extrusion company of India has several problems and they are as follows: Fluctuating price trends of raw materials, international competition, need for updating the technology.

But with these, the industry is also viewed to be having numerous opportunities as well. Infrastructural development along with smart city and renewable energy sectors is opening up new opportunities for aluminium extrusion profiles. Thirdly, the increasing lightweight and utility of steel products across industries also state the use of aluminium in different parts. Indeed, to take and sustain this opportunity’s advantage, companies require investment in research and development, put to advanced technologies use, and stay committed to qualities and sustainability.

Aluminium extrusion profiles have turned into a must-have material in many industries because of their flexibility, strength, and ability to adapt to environmental frontiers. The lightweight, heat-resistant, and corrosion-resistant features of these profiles make them suitable for applications that demand lightweight materials, such as construction, automotive, aerospace, transportation, and renewable energy. The advancement of infrastructure and development in India is likely to bring increased prospects for aluminium extrusion profiles in the market. The Aluminium Extrusion Company in India is poised to tap into these emerging markets by leveraging new technologies, improving environmentally sustainable manufacturing processes, and offering high-quality products. The aluminium extrusion industry has great potential to drive the future course of India’s industrial and economic development, in response to national initiatives such as green energy and smart cities.