When you need to pack and ship large items, a rigid boxes is the perfect solution. Not only are they sturdy and durable, but rigid boxes also offer some key benefits that can make your shipping process much easier. In this article, we’ll explore some of the key benefits of using high-quality rigid boxes for shipping purposes.

What are the benefits of using rigid boxes?

When it comes to shipping and storage, rigid boxes are a great option. Here are some key benefits:

They’re strong and durable- Rigid boxes can hold a lot of weight, which means they can protect your items from damage during transport and storage.

They’re easy to stack- Rigid boxes are designed to be stacked one on top of the other, which makes them ideal for use in houses for sale or storage facilities.

They’re barrier-free- Because rigid boxes are designed to be stacked, they create a barrier between your items and the outside world. This prevents contamination and protects your items from moisture and dirt.

What are the types of rigid boxes?

Rigid boxes come in a variety of shapes and sizes, each with unique benefits. Here are some of the most common types:

-Rectangular rigid boxes: Rectangular rigid boxes are the most common type, and they’re perfect for storing items that need to be tightly sealed. They make great storage containers for things like clothes or electronics, and they can also be used for food storage.

-Oval rigid boxes: Oval rigid boxes are similar to rectangular rigid boxes, but they have a more curved shape. This type of box is perfect for storing items that need more room to move around, like books or tools.

-Circular rigid boxes: Circular rigid boxes are the strangest type of box, and they’re perfect for storing items that need to be protected from moisture. They can be used to store items like wine or flowers, and they can also be used as decoration pieces in your home.

Read More About: custom sleeves boxes

-Custom rigid boxes: If you need a custom rigid box that’s not listed above, don’t worry – our team at Boxes Plus can help you create a box that fits your specific needs. We have years of experience creating custom rigid boxes, and

What are the best materials for rigid boxes?

There are many materials that can be used for rigid boxes, but some of the most popular options include wood, metal, and plastic. Each of these materials has its own set of advantages and disadvantages, so it’s important to choose the right one for your specific application.

Wood is the most traditional material for rigid boxes, and it’s often considered the best option because it’s strong and flexible. However, wood can be expensive and difficult to work with, so it’s not always the best choice for small businesses or applications that require high levels of precision.

Metal is another popular option for rigid boxes, and it has several advantages over wood. Metal is strong and durable, which makes it a good choice for applications that need heavy duty boxes. Additionally, metal doesn’t decay or rot over time, which makes it a good option for long-term use.

Plastic is another common material for rigid boxes, and it has several advantages over both metal and wood. For example, plastic is lightweight and easy to work with, which makes it a good option for applications that need small boxes that don’t require a lot of strength. Additionally, plastic doesn’t corrode or rust over time, making it a good choice for

How to choose the right type of rigid box for your project?

There are many factors to consider when choosing the right type of rigid box for your project, such as the material, dimensions, and intended use. To help you choose the right box for your needs, here are some key benefits to consider:

Material: Rigid boxes can be made out of a variety of materials, depending on your specific project requirements. Some popular options include metal, wood, and plastic.

Dimensions: The dimensions of a rigid box can also vary depending on your specific project requirements. For example, a small rigid box may only need to measure in at around 4 inches by 4 inches by 8 inches, while a large rigid box may be up to 18 inches by 18 inches by 24 inches.

Construction: A rigid box can either be constructed from one solid piece of material, or it can have multiple pieces that are glued or screwed together.

Rigid boxes can be made out of a variety of materials, depending on your specific project requirements. Some popular options include metal, wood, and plastic. The dimensions of a rigid box can also vary depending on your specific project requirements. For example, a small rigid box may only need to measure in at around 4 inches by 4 inches by

Conclusion

If you’re in business, then you know the importance of having a strong and reliable marketing strategy. With that in mind, it’s important to make sure your boxes are high quality – after all, they will be carrying your brand and message to potential customers.

Here are some key benefits of using high-quality custom rigid boxes:

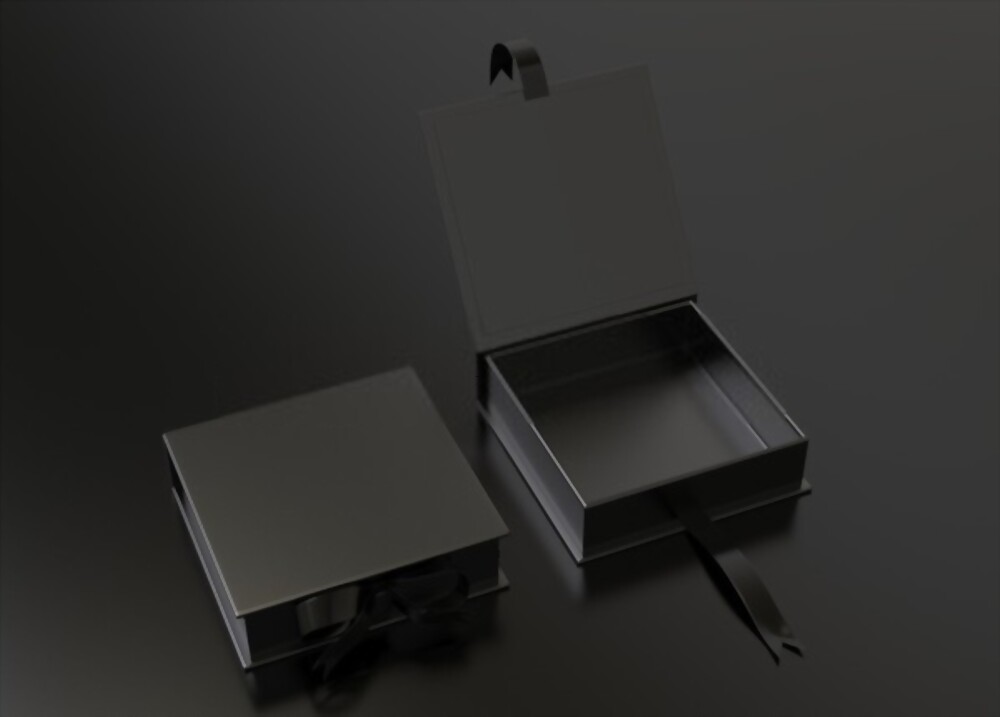

• They look professional and classy: A good box will look sleek and sophisticated, which will help your company stand out from the competition.

• They’re sturdy and durable: Your boxes should be able to handle a lot of wear and tear without breaking down. This is especially important if you have products that need to travel frequently or if you sell products that could potentially be damaged by shipping (ie., fragile items).

• They can promote safety: Make sure your boxes are safe for consumers to open – failure to do so could lead to injury. For example, some companies opt for tamper-resistant seals on their boxes so that unauthorized access isn’t possible.