Flange spreaders are essential in various industries, designed to safely and efficiently separate flanges. Moreover, flange spreaders avoid the risk of incidents while manually trying to pry flanges apart. This saves the workers from potential harm and ensures the equipment functions well. Many of these bond spreaders have many variants that different distributors offer to meet various needs, thus making it easier for different companies to look for the right tool to address their specific tasks. Investing in quality flange spreaders could help businesses ensure safety and smoothen their processes, making the workplace even more productive.

Know how flange spreaders enhance safety in maintenance tasks

By investing in these, the organisation protects its workers and contributes to a better operational environment that is bound to be more efficient and reliable. Flange spreaders, in this regard, are an invaluable asset in ascertaining smooth and safe maintenance processes.

Improved accessibility to confined spaces

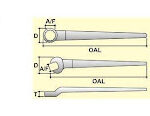

Flange spreaders separate ring-shaped flanges and flat surfaces used in connecting pipes or other fittings. Maintenance personnel have always found working between a pair of such flanges quite uneasy. Hence, flange spreaders safely and effectively drive a wedge to create enough room to work comfortably. By improving access, workers can perform tasks much more easily. Maintenance crews can use flange spreaders to help them avoid injury.

Minimizing the risk of damage to flanges

When performing maintenance, which requires opening or adjusting flanges, the flanges may become damaged. Most such incidents occur because incorrect tools or procedures to start the operation cause the flange to bend or break. Repairing this may be quite costly and time-consuming. Flange spreaders are designed to act exactly in such tasks with even pressure to reduce the possibility of damage during maintenance.

Improving worker safety

One of the top priorities for any maintenance environment is safety. Flange spreaders considerably enhance workers’ safety. When trying to separate such flanges either by hand or using other tools, workers are likely to slip or lose control, increasing the likelihood of injury. Flange spreaders provide controlled mechanical separation that reduces the chances of accidents. Not only that but the safer the worker is, the better the team in general.

Facilitating efficient maintenance

Efficient maintenance is what makes an operation run smoothly. Flange spreaders ease the process of accessing flanges and thus save the worker a lot of time and headaches. Since these tools simplify the operation of opening and closing a flange, they decrease the overall man-hours required for maintenance activities. This efficiency saves time and resources. Faster completion of maintenance tasks allows returning to normal operations sooner.

Best practices promotion in maintenance

When the appropriate tools are available, workers are most likely to follow the set safety protocols and guidelines, further enhancing this new safety and efficiency culture within the organisation. It helps train employees on using flange spreaders while demonstrating safety while operating tools. One also inculcates a sense of responsibility in employees regarding the execution of all work, which reduces the incidence of incidents and accidents at work.

Final words

To sum up, flange spreaders make maintenance operations safer by providing a safe and efficient way of separating the flanges. By design, they reduce injuries and damage to equipment, making them indispensable tools in many industries. With the help of flange separator tools, maintenance can be efficiently and safely carried out by workers without any danger that can emanate from manual methods. Investing in such tools improves operational efficiency and offers a safer environment in which to work.